| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | XCE |

| Model Number : | XCEHDI PCB |

| Certification : | CE,ROHS, FCC,ISO9008,SGS,UL |

| Price : | negotiation |

| Supply Ability : | 1, 000, 000 PCS / week |

What is HDI PCB

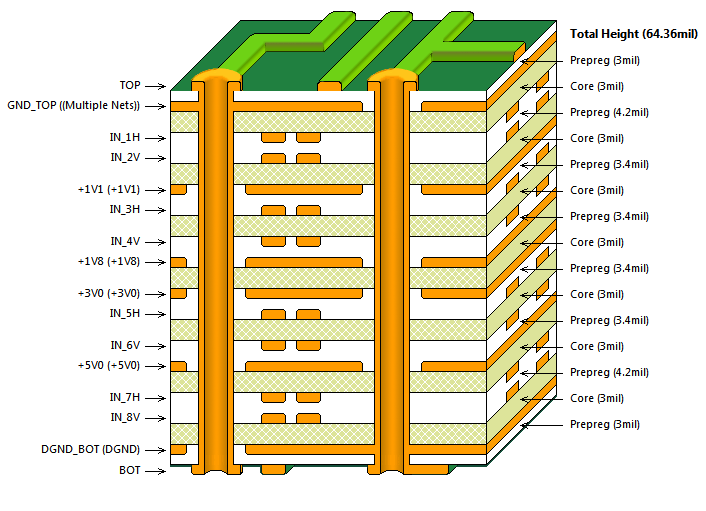

High density interconnects (HDI) PCB, represent one of the

fastest-growing technologies in PCBs. Because of its higher

circuitry density than traditional circuit boards, the HDI PCB

design can incorporate smaller vias and capture pads, and higher

connection pad densities. HDI Boards contain blind and buried vias

and often contain micro vias of 0.006 or less in diameter.

By using HDI technology, designers now can place more components on both sides of the raw PCB if desired. Now as the development of via in pad and blind via technology, it allows designers to place smaller components closer together. This means faster transmission of signals and a significant reduction in signal loss and crossing delays.

HDI PCB is frequently found in mobile phones, touch-screen devices, laptop computers, digital cameras, 4G network communications, also prominently featured in medical devices.

Advantages of HDI PCB

The most common reason for using HDI technology is a significant

increase in packaging density. The space obtained by finer track

structures is available for components. Besides, overall space

requirements are reduced will result in smaller board sizes and

fewer layers.

Usually FPGA or BGA are available with 1mm or less spacing. HDI technology makes routing and connection easy, especially when routing between pins.

Function improved by HDI PCB:

1.Denser trace routing

2.More stable power

3.Reduce interference inductance and capacitance effects

4.Improve signal integrity in high-speed design

Accelerate Development with HDI Printed Circuit Boards

1.Easier to place SMD components

2.Faster routing

3.Reduce frequent relocation of components

4.More component space (also by Via-in-Pad)

Feature | Capability |

Number of Layers | 4-30 layer |

Quality Grade | IPC 6012 Class 2,IPC 6012 Class 3 |

Material | Tg 140°C FR4,Tg 150°C FR4,Tg 170°C FR4 ,Special material |

Thickness | 0.4-6.0mm |

Min Track/Spacing | 2-8mil |

Min Hole Size | 0.15mm-0.3mm |

Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green |

Silkscreen | White, Black,Yellow,Blue |

Surface Finish | Immersion gold,OSP,Hard gold,Immersion Silver |

Finished Copper | 0.5-13oz |

Build time | 5-10 days |

Lead tim | 2-3 days |

The digital world is getting complex hour by hour whereas the hardware associated with it is getting drastically smaller. The advantages of HDI PCBs are numerous, starting with more interconnections in smaller areas. This results in the miniaturization of boards that can be used in many applications.

Your computers are no longer heavy. They are sleek and sexy. You can work on your laptop and keep your business running while you board a flight. You can also watch your favorite action movie on your smartphone, some of which are way powerful than your laptops. Or you can just plug in your wireless headphones and get into the groove. Mankind is fond of electronics and it has become a part of our lives. In this era, all the electronic devices are designed for portability. Electronic devices are being designed for human convenience. All this was possible because of the miniaturization of the components and PCBs inside the electronic devices.

The PCB industry plays a prominent role in the development of all the electronic gadgets. Let it be a pacemaker in someone’s chest or the motherboard in a programmer’s workstation, PCB made it possible for creating crucial electronic devices.

As the size of the components shrinks, printed circuit board manufacturers adapted to the changing trends. This led to the birth of HDI design. This has made PCBs smaller, denser with higher component count, and faster.

|