| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | XCE |

| Model Number : | XCEM |

| Certification : | CE,ROHS, FCC,ISO9008,SGS,UL |

| Price : | negotiation |

| Payment Terms : | T/T,Western union |

| Supply Ability : | 1, 000, 000 PCS / week |

| Delivery Time : | 5-10 days |

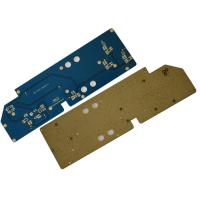

2 Layer Taconic Radio Frequency Board

TACONIC high-performance insulation materials for the microwave,

radio frequency (RF) and high-speed digital signal processing market PTFE / woven glass fiber woven

sheet.

Customize Taconic PCB Board,we can according to your gerber file,tell us the quantity,size,finished surface,we will Customize TLX-8,TLX-9,TLC-32,TLY-5,RF-60A,CER-10,RF-30,TLA-35 PCB board,use to Antenna, radar, microwave, suitable for high-speed signal transmission,Taconic Board design requirements: multi-layer design of the prepreg dielectric constant, according to the way to calculate the actual mixing dielectric constant and impedance

Radio Frequency board is RF Board, referring to the radio frequency, high frequency signal. See the performance requirements of the circuit board can be ordinary FR4 epoxy glass fiber, Teflon can also be a special microwave substrate.In addition to the general principle of printed circuit board on the RF circuit PCB - consider the current size, but also must consider the characteristic impedance of the printed line, strict impedance matching, printed circuit impedance control must be considered in the PCB production. The characteristic impedance of the printed wire is related to the material properties and physical parameters of the PCB, so the PCB designer must know the performance of the PCB

RF board standard:

1, low-power RF PCB design, the main use of standard Taconic material

2, RF PCB, the various components should be arranged closely to ensure that the connection between the various components the shortest.

3. For a mixed-signal PCB, the RF part and the analog part should be far away from the digital part (the distance is usually at least 2cm, at least 1cm). The ground of the digital part should be separated from the RF part.

4, in the choice of components in high-frequency environment, the use of surface mount devices as much as possible. This is because the surface mount components are generally small in size and the leads of the components are short.

| Specifications | Technology | Notes |

|---|---|---|

| Number of Layers | 1-40 Layers | |

| Board Materials | FR4 (Tg – 135C, 145C, 170C, 180C) Rogers RO4350 Rogers RO4003 Rogers5880 Rogers3003 Rogers3010 F4B Taconic:TLX-8,TLX-9,TLC-32,TLY-5,RF-60A,CER-10,RF-30,TLA-35 Teflon Arlon AR350 | We normally keep these materials in stock. If you need a material that is not listed here, please contact us and we can order it for you. |

| Final PCB Thickness | 2 Layer – Min .005” Max .250” 4 Layer – Min .015” Max .250” 6 Layer – Min .025” Max .250” 8 Layer – Min .031” Max .250” 10 Layer – Min .040” Max .250” 12 Layer – Min .047” Max .250” 14 Layer – Min .054” Max .250” 16 Layer – Min .062” Max .250” 18 Layer – Min .093” Max .250” 20 Layer – Min .125” Max .250” 22 Layer – Min .125” Max .250” >24 Layer – Min .125” Max .250” | |

| Core Thickness | Min .0025” | |

| Maximum PCB Size | 2 Layer 20” x 28” Mulitlayer 16” x 26” | |

| Minimum Conductor Space | 0.003” | |

| Minimum Conductor Width | 0.003” | |

| Minimum Drill Hole Size | 0.006” | |

| Finish Plating / Surface Finishes | HASL – Leaded Solder Tin/Nickel HASL – Lead Free Solder Electroless Soft Gold Wire Bondable Soft Gold Nickel Flash Gold Electroless Nickel Immersion Gold OSP Electrolytic Nickel /Hard Gold and Selective Gold Immersion Silver Immersion Tin Carbon Ink ENIG | |

| Finished Copper – Outer Layers | 1oz Cu – Min .004” Trace/Space 2oz Cu – Min .005” Trace Space 3oz Cu – Min .008” Trace/Space 4oz Cu – Min .010” Trace/Space 5oz Cu – Min .012” Trace/Space | We can manufacture higher ounces of copper depending on the specs. Please let us know how much you would like when sending us your PCB specs. |

| Finished Copper – Inner Layers | .5oz Cu – Min .004” Trace/Space 1oz Cu – Min .005” Trace/Space 2oz Cu – Min .006” Trace/Space 3oz Cu – Min .010” Trace/Space 4oz Cu – Min .012” Trace/Space | |

| Inner Layer Clearances | Min .008” Minimum Finished Hole Size Final Thickness <=.062” – .006’ Hole Final Thickness .150” – .014” Hole Final Thickness .093” – .010” Hole Final Thickness .200” – .018” Hole Final Thickness .125” – .012” Hole Final Thickness .250” – .020” Hole | |

| Gold Fingers | 1 to 4 edges | |

| Solder Mask Type | Per IPC-SM-840 LPI Soldermask Peelable Soldermask | |

| Solder Mask Colors | Green/Green Matte White Black/Black Matte Clear Blue Top and Bottom Mix Red One or Both Sides Mix | |

| Silkscreen Type | Thermal Cure Epoxy Ink LPI Ink | |

| Silkscreen Colors | White Black Yellow Top and Bottom Mix Red One or Both Sides Mix Blue | |

| CNC Functions | Scoring Edge to Edge Plated Counter bores Skip Scoring – .250” Spacing Milling 30 or 60 Degree Score Angle Blind and Buried Vias 30 to 100 Degree Countersink Controlled Z Axis Route 15 to 45 Degree Gold Finger Bevel Castellated Barrels Counterbores Offset or Recessed Beveling Plated Countersinks | |

| Other PCB Services | Blind and Buried Vias Plated Slots Specified Dielectric Tented Vias Controlled Impedance Solder mask Plugged Vias Via Caps (Solder Mask) Conductive Filled Vias | |

| Quality / Testing | Inspect to IPC Class III Continuity Resistance – 10 to 20 Ohms Net List Test per IPC-356D Isolation Resistance – 2 to 30 Megaohms Test Voltage – 100 to 250 Volts Minimum SMT Pitch 0.5 mm | |

| Tolerances | PTH Hole Size – +/- .002” Front to Back – +/- .002” NPTH Hole Size – +/- .001” Solder Mask – +/- .002” Tooling Holes – +/- .001” Hole to Pad – +/- .005” |

QUALITY GUARANTEED

Labview control software and GUI for instrument control and test routines

ISO 9001:2008 certification

UNE.EN 9100 certification

Application of MIL standards as needed

Application of ECSS standards as needed

Airborne / space / ground equipment

Hi-Rel design and manufacturing procedures

Why Choose Us?

1. Your inquiry related to our products or prices will be replied in 24hrs.

2. Well-trained and experienced staffs to answer all your enquires in fluent English

3. OEM&ODM, we can help you to design and put into product.

4. Distributorship are offered for your unique design and some our current models

5. Protection of your sales area, ideas of design and all your private information

Trade Terms:

1. Payment: T/T in advance (Western Union , PayPal is welcomed)

2. Sample can be delivered in 3 days

3. Shipping freight are quoted under your requests

4. Shipping port: Shen zhen,Mainland China

5. Discounts are offered based on order quantities

6. MOQ: 1PCS

|